Density is the most valuable geophysical logging information and therefore its accuracy is critical for all subsequent geophysical and petrophysical data interpretation.

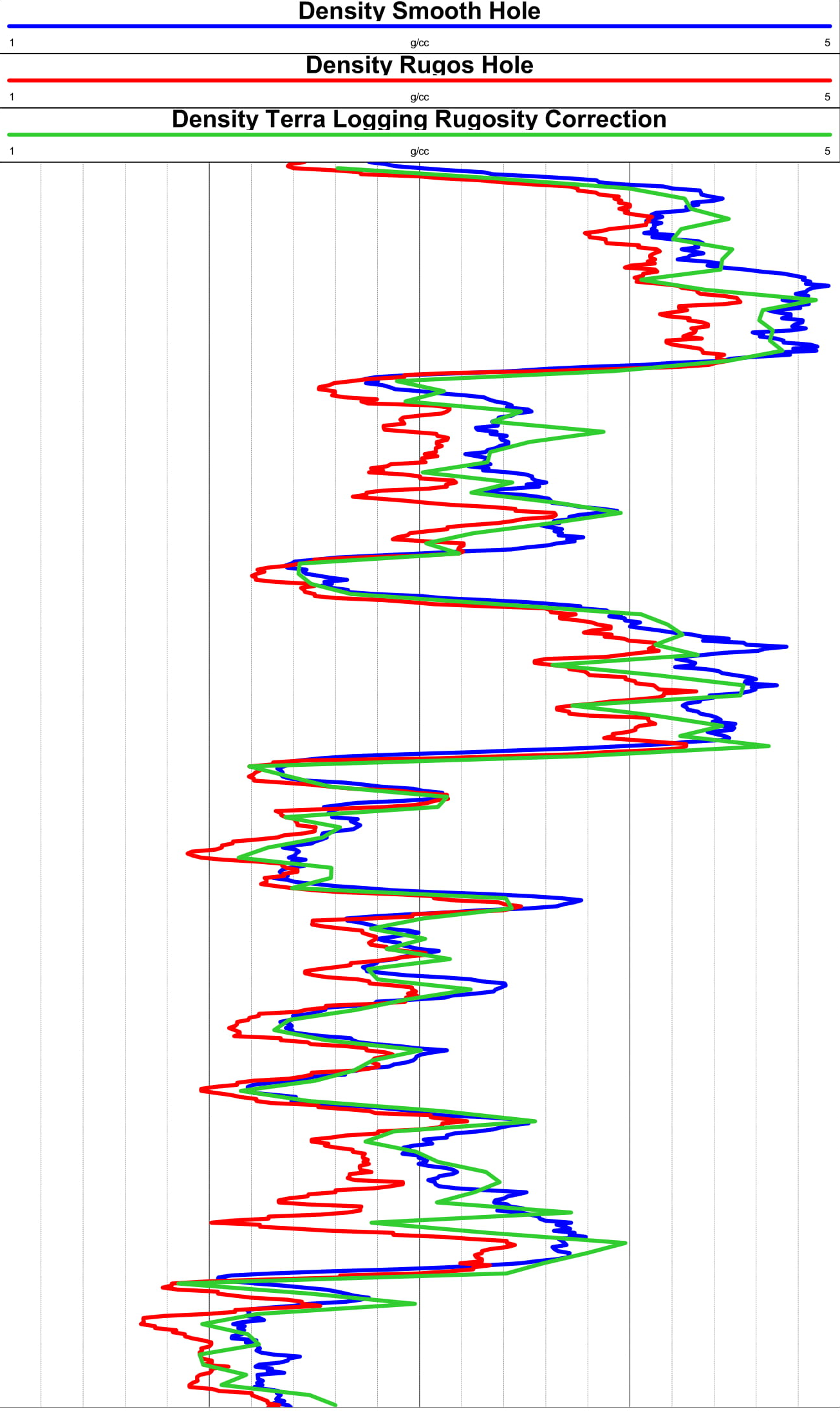

Measurements made with single detector gamma-gamma density tools are quite accurate if the borehole wall is smooth and not covered with mudcake. However, borehole rugosity and mudcake causes the measured density usually too low, because it includes the effects of the low-density borehole fluid, water or air that occurs in the path of the gamma rays.

The effect of the mudcake, borehole fluid, and rugosity was largely overcome by the development of compensated density probes (dual density) that contains two collimated detectors at different spacing from the source.

Single vs Dual Density Logging Considerations

Single detector and short spaced detector density are high accuracy and low resolution as compared with long spaced detector, which is low accuracy and high resolution.

Therefore an accurate single detector density reading may retrieve valuable information otherwise lost, thin beds and ore nuggets, etc.

Iron Ore Considerations

Density logging tools were developed to work in the petroleum industry. As a result the devices have evolved to produce very accurate results with good hole conditions in sedimentary rocks (having densities up to around 3 g/cm3).

Reverse circulation drilling and formation densities above 4 g/cm3 are regularly seen in the iron ore industry.

These high densities when combined with reverse circulation drilling, affect the measurement in several ways including: attenuating count rates, decreasing depth of investigation and diminishing tool contact with the borehole wall.

The drilling process introduces artificially lower densities due to fracturing and increased rugosity around the borehole.

Electron density and borehole rugosity corrections that improve gamma gamma density accuracy enhances density accuracy.